Micronfilter USA™

About us

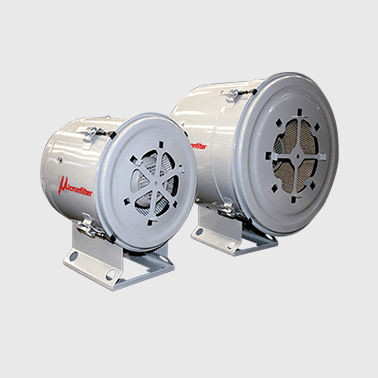

At MICRONFILTER USA ™, we're driven by a passionate team of skilled engineers and dedicated sales professionals who have devoted their careers to revolutionizing workplace ecology, specializing in machine tool mist collection and coolant filtration. Micronfilter USA™ has swiftly evolved into a formidable, competitive, and meticulously structured company, poised to rival industry giants in this sector. Our remarkable growth is only the beginning of our journey, as we're determined to set the course for sustained expansion for many decades ahead. From our strategically located stock in Texas, we offer an extensive range of products including mist collectors, dust collectors, gravity bed filters, and more, designed to transform the way industries address environmental challenges and optimize performance.

Choose The Product Area

Productsindustries/applications

Automotive

Aerospace

Medical Devices

Gun Manufacturing

Steel Mills

Oil and Gas